Wastewater Clarifiers Meet New Molybdenum Regulations at Hazardous Waste Landfill

Challenge

A hazardous waste landfill required an upgrade to its wastewater treatment system to comply with new, more stringent molybdenum regulations. Faced with a tight deadline and complex process considerations, the landfill turned to Monroe Environmental to help design and implement a solution.

Solution

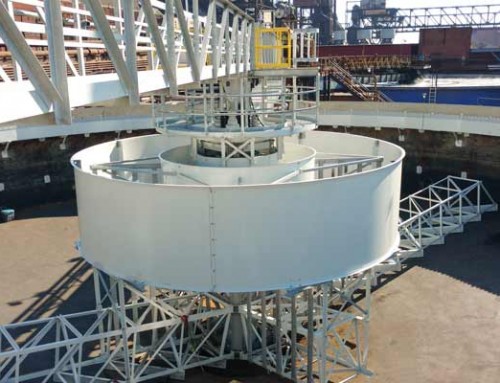

Monroe worked closely with the landfill’s engineers to develop a system that would effectively precipitate, coagulate, and remove metals and TSS to meet the regulation. The design consisted of several chemical mixing stages followed by a Vertical Plate Lamella Clarifier to separate solids prior to final filtration. The sludge from the clarifier then went to a 17-foot diameter Circular Thickener and 5,000-gallon sludge conditioning tank before being pumped to the dewatering system.

The system was designed not only to meet the effluent requirements, but also to fit within a specific site layout having footprint and elevation constraints.

Result

The wastewater treatment system was installed and commissioned under the supervision of the Monroe Field Service team. The new clarifiers effectively reduced molybdenum concentrations in the landfill’s contact water, allowing them to operate within their permitted parameters. The system was rated for 125 GPM.

Monroe’s expertise in providing integrated wastewater treatment solutions, from design to implementation, helped the landfill overcome regulatory pressure and successfully meet its treatment objectives.