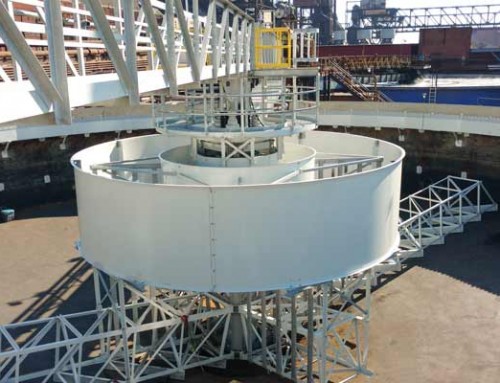

Monroe Clarifier Provides Cost-Effective Expansion of Manufacturing Capacity via Wastewater Reclamation and Re-Use

Challenge

A PVC resin manufacturing plant was looking to expand its operations without purchasing additional water supply, a limiting factor in the expansion decision. In order to do so, the plant had to clarify and re-use the process water that was being discharged from a centrifuge. This wastewater contained PVC fines that had to be removed before the water was suitable for re-use.

Solution

Monroe designed and built a 600 GPM Horizontal Clarifier (see above left) to separate the suspended solids from the wastewater. High-density polyethylene parallel plates enhanced the clarifier’s settling capabilities and allowed for successful separation of the PVC fines from the process water. These plates provided approximately the same settling capacity as a 40-foot diameter circular clarifier. The settled particulate was then discharged from two large pyramid hoppers for disposal.

Result

Plant operators were able to reclaim 85% of the clarified process water for re-use. As a result, the plant was able to expand their operations as planned without purchasing additional water supply. Based on their positive experience with Monroe, the engineers purchased another clarifier (150 GPM Horizontal Clarifier with drag conveyor, see above right) for use during another stage of their manufacturing process.