Leader in Air Pollution Control Systems

Does your plant need to reduce emissions?

-

Acid & alkaline gasses

-

Particulate matter – PM 10/2.5

-

Condensables, aerosols, & opacity

-

VOCs, odor, & fumes

-

Oil, mist, & dust

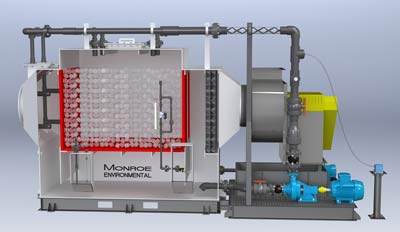

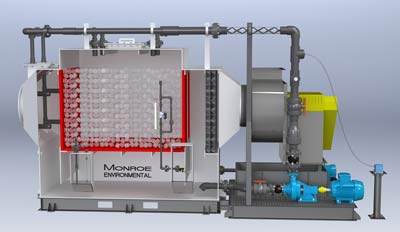

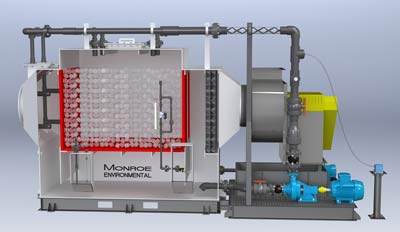

Monroe Environmental designs and manufactures custom air pollution control systems and equipment for eliminating and minimizing a wide spectrum of air pollutants and regulated emissions from virtually all types of sources and applications.

Have technical questions about air pollution control systems?

Air Pollution Control Applications & Process Experience

Monroe Environmental has extensive experience with a wide variety of applications and processes for air pollution control. Click on a pollutant below to learn more about our approach to treating these contaminants.

650 ACFM Packed Tower Scrubbing System, polypropylene construction for SO2 removal.

Monroe Dual Throat Venturi Scrubber with drag conveyor for solids recovery at insulation plant.

4,500 CFM Carbon Adsorber to exhaust clean room at an automotive battery plant.

Value-Added Engineering, On‑Site, and Support Services

Auxiliary Equipment, Components, & Packaged Systems

In addition to providing air pollution control systems, Monroe offers an array of equipment, components, and devices typically needed for enabling a complete turnkey installation. These include but are not limited to the following:

- Ductwork, dampers, and stacks

- Control and instrumentation systems

- Chemical storage and feed systems

- Blowdown and water treatment systems

- Carbon and filter media

- Pumps, piping, valves, and fittings

Technical and Engineering Support Services

Technical and Engineering Support Services

- Evaluations and troubleshooting of existing systems and problems

- Assessments for new and replacement systems

- Environmental permitting and compliance assistance

- System sizing and general arrangement drawings

- Mechanical, electrical and structural requirements

- PLC programming and HMI interfacing

- Cost estimating and budgeting

- Testing and gas stream analysis

- Air quality impact analysis

- And more

Industries Served

Rental, Pilot, and Testing Programs

Resources & Literature

Recent Case Studies

Air | 250,000 CFM Mist and Dust Collection Solution for Construction Equipment Manufacturer

A high-production manufacturing facility that makes engines for heavy-duty construction equipment was expanding operations and needed to control mist, fumes, and dust generated from various machining, grinding, and polishing centers on the plant floor.

Air | Multi-Stage Mist Collector for Zinc Strip Rolling Mill Upgrade

A zinc strip rolling mill was having repeated issues with its existing fume/mist collection system – short filter life and frequent maintenance events – which added up to too much $$ being spent.

Air | Extending the Life of an Existing Fume Scrubber

Monroe Environmental is expert in troubleshooting and rebuilding a competitor’s wet scrubbing system to bring it up to like-new efficiency and performance standards.