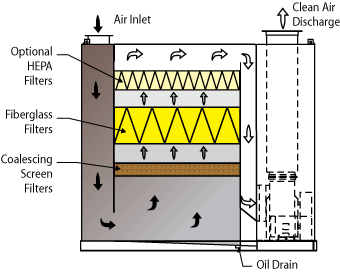

The Monroe Multi-Stage Oil Mist Collector is designed to collect and remove airborne oil mist, smoke, and submicron vapors generated by operations such as high production machining and cold forming. It is a multiple stage collector that has proven capabilities exceeding 99% efficiency on many installations.

Multi-Stage Oil Mist Collector

The Monroe Multi-Stage Oil Mist Collector is available in capacities from 500 CFM to over 80,000 CFM in a single unit and may be integrated with existing ductwork and ventilation systems.

After installation of Monroe Multi-Stage Oil Mist Collectors, high production machining areas using water soluble, synthetic or mineral coolants can discharge clean, filtered air back into the work area, reducing system costs.

Air flow to filter media ratio is held low to prevent saturation blocking. This eliminates down-time due to collector malfunction and minimizes periodic changing of filter media.

The Monroe Multi-Stage Oil Mist Collectors are designed for continuous draining during operation, resulting in typical filter media life of 4,500 hours or more, even under heavy inlet loading.

Design Leadership

The Monroe Multi-Stage Oil Mist Collector, with more filter media, longer operating time between filter changes, and higher collection efficiency, outperforms all other collectors in its class. Because of slower internal velocities through the collector, media replacement and maintenance labor costs are reduced. Collected oil mist and solids are continuously drained from the media without shut-down, significantly prolonging filter life and lowering overall operating costs.

Many Configurations Available

Monroe Multi-Stage Oil Mist Collectors are available in various configurations to meet your needs. Units can be suspended from the ceiling or other supporting structures to conserve floor space.

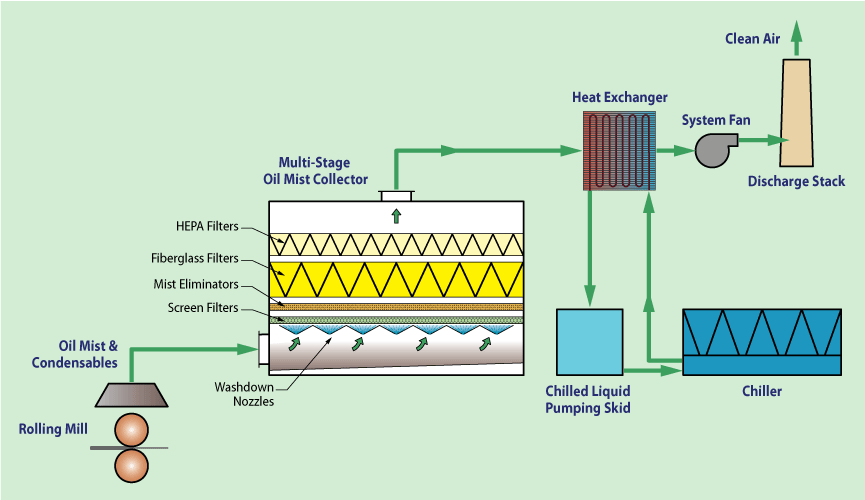

Meeting Condensable Particulate & PM2.5 Regulations

Monroe’s application and process engineers can assist with evaluating your specific requirements and designing an appropriate solution.

The Monroe Multi-Stage Oil Mist Collector can meet the most stringent regulations for PM2.5 and condensable particulate matter. See Recent Project

Recent Projects

Multi-Stage Oil Mist Collector Applications

Resources & Literature

Recent Case Studies

Air | 250,000 CFM Mist and Dust Collection Solution for Construction Equipment Manufacturer

A high-production manufacturing facility that makes engines for heavy-duty construction equipment was expanding operations and needed to control mist, fumes, and dust generated from various machining, grinding, and polishing centers on the plant floor.

Air | Multi-Stage Mist Collector for Zinc Strip Rolling Mill Upgrade

A zinc strip rolling mill was having repeated issues with its existing fume/mist collection system – short filter life and frequent maintenance events – which added up to too much $$ being spent.

Air | Oil Mist Collector for Fiber Plant

Monroe Multi-Stage Mist Collector operates at 95% efficiency, treating 0.3 micron sized oil mist particles for synthetic fiber plant.