High Torque Thickener Clarifier for Gypsum Sludge

Challenge

A gypsum manufacturing plant was having trouble effectively treating its plant wastewater. Existing slant plate clarifiers were misapplied to the process and were unable to properly separate the dense, sticky solids contained in the liquid stream. Furthermore, if the solids were not properly agitated and pumped out in a timely manner, material setting could damage equipment and stop production.

Solution

Monroe Environmental was called upon to provide a solution for the wastewater treatment problem. After careful evaluation, several site visits, and consultation with operators and engineers, Monroe proposed replacing the plate clarifiers with a high torque Circular Thickener Clarifier. This technology would allow for uninterrupted settling and proper agitation of the separated solids before setting occurred.

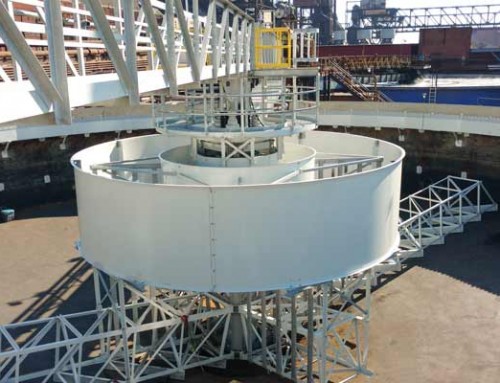

Scope of supply included a 45 ft. diameter circular thickener on legs with tank, supports, drive mechanism, bridge, sludge rakes, skimming system, and piping. Additional equipment supplied included an access staircase and a heavy duty sludge pump. The system was rated for 800 GPM.

Result

Monroe designed and fabricated the unit at its Monroe, MI facility and was able to pre-fit the tank and internals in the shop to minimize assembly issues in the field. Monroe also provided extensive on-site assistance and guidance to the installation contractor to ensure a smooth and efficient installation and start up process.

Feedback from plant personnel is that “The clarifier is working great!”