Water and Wastewater Treatment Clarifiers and Separators

Does your plant need to treat a contaminated liquid stream?

-

Suspended (TSS) & dissolved (TDS) solids

-

Metals precipitation & reduction

-

Oil/FOG separation & recovery

-

Ammonia & VOC stripping

-

Mobile water treatment & rentals

Monroe Environmental designs and builds a broad range of water and wastewater treatment systems and equipment for eliminating and minimizing a wide spectrum of pollutants from virtually all types of water and wastewater sources and applications.

Have technical questions about water and wastewater treatment systems?

Monroe’s Water & Wastewater Treatment Systems & Equipment

Water and Wastewater Treatment Applications & Process Experience

Monroe Environmental has extensive experience with a wide variety of applications and processes for water and wastewater treatment. Click on a pollutant or process below to learn more about our approach to treating these contaminants.

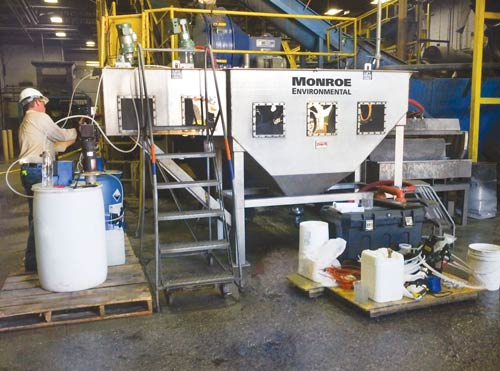

750 GPM Vertical Plate Clarifier with Thickener

Low profile Horizontal Clarifier–Oil/Water Separator for offshore drilling rig deck wash solids/oil clarification.

Value-Added Engineering, On-Site, and Support Services

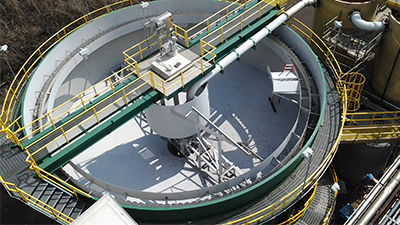

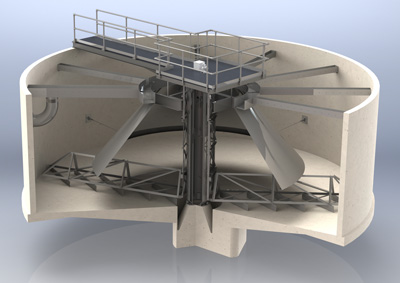

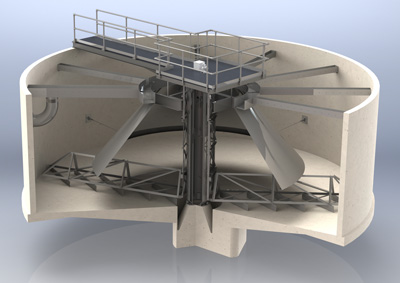

Inspection of a 90 ft. Riser Pipe Circular Clarifier

Auxiliary Equipment, Components, & Packaged Systems

Auxiliary Equipment, Components, & Packaged Systems

In addition to providing water and wastewater clarifiers and separators, Monroe offers an array of equipment, components, and devices typically needed for enabling a complete turnkey installation. These include but are not limited to the following:

- Control and instrumentation systems

- Chemical storage and feed systems

- Equalization and storage tanks

- Dissolved air floatation

- Sludge handling & dewatering systems

- Filtration & polishing systems

- Access platforms, ladders, stairways, and walkways

- Pumps, piping, valves, and fittings

Technical and Engineering Support Services

Technical and Engineering Support Services

- Evaluations and troubleshooting of existing systems and problems

- Assessments for new and replacement systems

- Environmental permitting and compliance assistance

- System sizing and general arrangement drawings

- Mechanical, electrical and structural requirements

- PLC programming and HMI interfacing

- Cost estimating and budgeting

- Testing and water quality analysis

- And more

Industries Served

Resources & Literature

Recent Case Studies

Water | Secondary Clarifier Rebuild Featuring X‑Flo Mobile Clarifier for Emergency Bypass

With Monroe’s X‑Flo Mobile Clarifier™, a permanent clarifier upgrade/replacement can be done at any time while keeping the plant treating water throughout the whole process.

Water | Vertical Plate Clarifier Removes Mercury & Humic Acid

A company that produces testing and measurement equipment needed to remove solids containing mercury and acid fines from their incoming process water stream.

Water | API Separator for FOG Removal

Monroe engineers were able to help one of the largest potato and corn chip producers in the world meet a strict deadline to achieve lower levels of FOG in their effluent discharge.