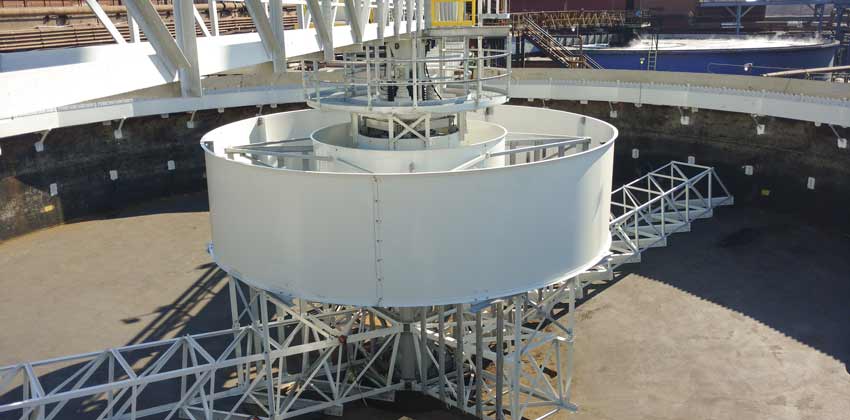

The specification and design of a clarifier for wastewater treatment involve several key considerations to ensure effective performance and compliance with regulatory standards. These include: capacity and flow rate, settling characteristics, geometry and configuration, inlet and outlet design, sludge removal systems, controls systems, materials of construction, and more.

Clarifier Drive Torque: Operating Use of Torque

William H. Boyle, P.E.2023-10-09T11:53:48-04:00Normally a clarifier runs at one torque value for 90 – 98% of the time. The drive unit should be designed for this running torque and should protect from excessive loads that would require it to run above its design requirements. Optimum ratings for running, alarm, and shut-off should be specified for a clarifier drive unit based on the intended use of the clarifier.