If you plan to rebuild or retrofit a water or wastewater treatment clarifier, call Monroe Environmental. We specialize in the repair, retrofit, replacement and general upgrading of clarifiers. We recognize that up-time is critical; we’ve replaced whole systems in as little as 3 days — from empty tank to new internals installed and operating.

Why Rebuild or Retrofit Existing Clarifiers?

Rebuilding and replacing the internals of a concrete or steel tank clarifier is a quick, cost-effective solution versus constructing an entirely new system. The clarifier tanks often maintain a suitable operating condition while the skimmer arm, center well, drive assembly, and sludge rakes corrode and wear beyond an acceptable level.

The benefits of a Monroe Environmental Clarifier Rebuild are straightforward and simple:

- Faster installations & reduced total cost

- Minimal clarifier downtime

- Improved performance

- Reduced future maintenance costs

These benefits are realized because we are often able to fully assemble clarifier equipment before it ships to the job site. In such a case, we inspect and test every bolt, weld, and panel to make sure that each component fits together perfectly before it is shipped to site and installed. This key step can be the difference between a few days of simple installation or weeks of fitting, engineering, and re-working equipment in the field. By reducing installation time, projects can often be completed ahead of schedule with minimal labor cost.

Call or e-mail us and one of our Application Engineers will contact you to review the details.

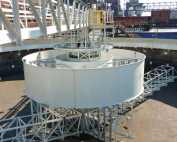

Rebuild of a Secondary Clarifier for municipal wastewater treatment

Clarifier Rebuild Examples

Vertical Plate Clarifiers: Retrofit at a Catalyst Plant

Before: Lamella plate clarifier with internal components that were warped, buckling, and in danger of collapsing under thermal stress.

After: Lamella plates installed after new supports for internal structural and process deficiencies were addressed.

Circular Clarifier: X-Flo Bypass for Truck Assembly Plant: 100% Uptime!

Vertical Plate Clarifiers: Rebuild of a Competitor’s Inclined Plate Clarifier

Vertical Plate Clarifier: Plating Company

Before (Photos 1 & 2): Vertical Plate Clarifier rebuild for a plating company. After (Photo 3): Refurbished Vertical Plate Clarifier leaving Monroe facility.

Secondary Clarifier: Municipal Wastewater Treatment

Before (Photo 1): Secondary Clarifier 130 ft. Clarifier rakes fully assembled in Monroe shop prior to shipment. Photo 2: Installation of rebuilt components at a 25 MGD WWTP. After (Photo 3): Secondary Clarifier ready to return to operation after just a three day installation.

Circular Clarifier: Chemical Manufacturing Plant

Before: Existing 55 ft. diameter Scraper Clarifier at chemical manufacturing plant. Middle photo: New Clarifier internals completely assembled in Monroe shop. After: Installation of new internals as well as drive, bridge, and walkway.

Primary Clarifier: Municipal Wastewater Treatment

Before (Photos 1 & 2): Upgrade of four 250 ft. Primary Clarifiers. The project included converting the sludge rakes to higher efficiency spiral scrapers and rehabilitating existing drive units, as well as replacing influent wells, column supports, weirs, baffles, and launders with a combination of mild, coated steel and non-corrosive stainless steel members. After (Photo 3): One of the Primary Clarifiers ready to return to operation.

Clarifier Rebuild Services

Resources & Literature

Recent Case Studies

Water | Secondary Clarifier Rebuild Featuring X‑Flo Mobile Clarifier for Emergency Bypass

With Monroe’s X‑Flo Mobile Clarifier™, a permanent clarifier upgrade/replacement can be done at any time while keeping the plant treating water throughout the whole process.

Water | Circular Clarifier for Steel Mill Upgrade

Monroe Environmental saves steel mill $145,000 on clarifier rebuild/retrofit for blast furnace wastewater and meets stringent performance requirements.

Water | Lamella Clarifier Retrofit

Rebuild of two underperforming Lamella Clarifiers to address the stresses of elevated liquid temperatures, and internal structural and process deficiencies.