The Monroe Cartridge Dust Collector is designed to provide continuous-duty collection and removal of airborne dust and particulate matter produced by manufacturing and processing operations at 99+% efficiency on many installations. Through the use of a Monroe Cartridge Dust Collector, these operations can discharge clean, filtered air back into the work area thereby reducing climate control costs.

Reverse Pulse Cartridge Cleaning

Continuous collection and removal of airborne dry dust and particulate matter (PM) with reverse pulse cleaning of bags or cartridges allows operation without shutdown.

Continuous collection and removal of airborne dry dust and particulate matter (PM) with reverse pulse cleaning of bags or cartridges allows operation without shutdown.

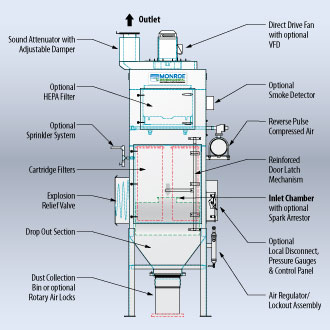

Improved Safety Features: Fire/Explosion Suppression Options

Monroe Environmental offers a wide variety of state-of-the-art features to maximize worker safety and minimize equipment damage, including fire and explosion suppression options for hazardous applications.

The Monroe Cartridge Dust Collector can also be fitted with specialty polypropylene cartridge filters to accommodate MQL (minimum quantity lubricant) machining operations, which is a highly attractive waste and energy reducing machining technology gaining acceptance in a variety of production plants.

- Backdraft damper – NFPA 69-2014 compliant

- Explosion relief valve – resealing pressure relief valve with opening detection

- Spark detection sensor – ductwork mounted single-infrared (IR) spark/flame detection sensor

- Spark arrestor – inline ductwork spark arrestor to smother and quench sparks and embers

- Smoke detector

- Sprinkler system with flow switch

- Inlet/outlet chemical suppression

- Flame retardant filters

- Spark resistant fan

- Explosion proof motor

Industrial Air Filtration: Dust Collection System Design

PM Reduction

The Monroe Industrial Cartridge Style Dust Collector is designed to provide continuous-duty collection and removal of airborne dust and particulate matter produced by manufacturing and processing operations at 99+% efficiency on many installations. Through the use of a Monroe Cartridge Style Dust Collector, these operations can discharge clean, filtered air back into the work area reducing climate control costs.

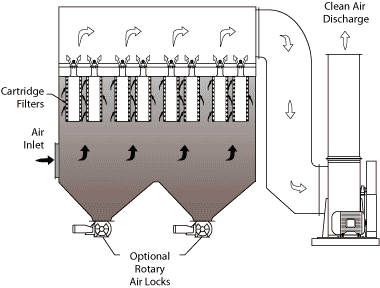

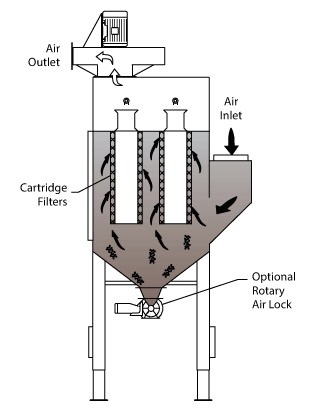

The Monroe Cartridge Style Dust Collector modular design incorporates high efficiency, pleated cartridge filters to achieve maximum filter surface area in a relatively small housing. The cartridges are designed to provide a low static pressure drop.

Cartridge cleaning is accomplished by reverse compressed air pulses through a few cartridges at a time, allowing continuous operation without shut-down. These reverse pulses, with a velocity of twice the speed of sound, break away caked dust from the cartridge so that it can drop the collector bottom.

Top Performance with Better Cartridge Filter Cleaning

The cartridges in the Monroe collector are mounted in a vertical position. This assures that when the collected dust is pulsed from the cartridges, it falls to the bottom of the collector.

In units with horizontal cartridges, dust pulsed from above cartridges falls onto cartridges below. This reduces filtration capability and additional maintenance for rotating cartridge is necessary. This is avoided in the Monroe unit. The Monroe cartridges are easily accessed with pull out racks when replacement is necessary.

- Assembly in Monroe shop

- Roof mounted system

- CNC plasma exhaust

- Sandblast & paint exhaust

- 30,000 CFM system

Recent Projects

Dust Collector Applications

Resources & Literature

Recent Case Studies

Air | 250,000 CFM Mist and Dust Collection Solution for Construction Equipment Manufacturer

A high-production manufacturing facility that makes engines for heavy-duty construction equipment was expanding operations and needed to control mist, fumes, and dust generated from various machining, grinding, and polishing centers on the plant floor.

Air | Dust Collector for Sandblasting

Monroe designed and installed a 6,000 CFM Cartridge Dust Collector to capture the exhaust from a sandblast and painting bay.