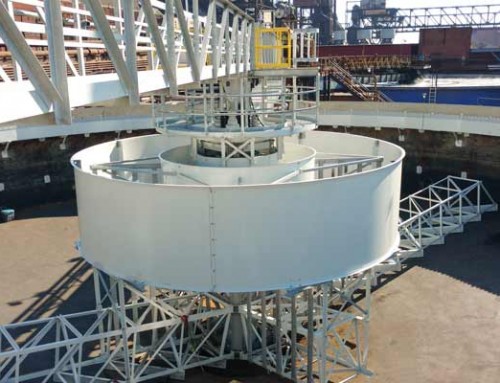

50 GPM Vertical Plate Clarifier Rental Pilot System used to trial an improved clarifier technology prior to full scale investment.

750 GPM Vertical Plate Clarifier with three pretreatment mixing tanks and integral sludge thickener to clarify process water at specialty insulation manufacturing plant. The system was purchased as a result of the successful pilot study.

Lamella Plate Clarifier Pilot Confirms Solution to Reduce TSS and Effluent Solids Carryover

Challenge

A manufacturer of thermal and fire insulation products faced significant challenges with their existing plate clarifier. The aging system was poorly designed and suffered from inefficiency, resulting in slugs of fibrous carryover in the effluent and problematic build-up in pre-treatment tanks. This short-circuiting impacted effluent quality and negatively affected downstream processes. It also increased maintenance costs. The company needed a reliable and efficient solution to eliminate these issues.

Solution

Having identified the design flaws with the existing system, Monroe Environmental was confident that its superior plate clarifier design would remedy the issues. To prove this out, they recommended a pilot study using their 50 GPM rental Monroe Lamella Plate Vertical Clarifier with Thickener (VCT). This pilot program was crucial in confirming the feasibility and effectiveness of the proposed clarifier system for the customer’s specific process.

Pilot Study Focus

The goal was to achieve the desired floc formation, settling, and effluent quality, while minimizing solids settling in the pre-treatment tanks. The pilot study demonstrated the critical relationship between a clarifier’s performance and important design factors such as proper floc conditioning, retention time, flow pattern, and sludge storage.

Key Features of the Monroe Lamella Plate Clarifier

- Optimized Floc Formation – The VCT’s design promoted the development of robust floc, which is crucial for efficient solids removal. Proper mixer and tank design also reduced settling in the pretreatment tanks.

- Stainless Steel Plates – The use of stainless-steel plates, combined with an improved plate orientation, minimized adhesion and build-up of solids in the separation section – a common problem with the previous system. This feature improved performance by helping to reduce solids carryover in the effluent, and it lowered maintenance costs.

- Integrated Sludge Thickener – The sludge thickener provided a significant boost to the overall sludge storage capacity. Separating the solids storage section from the inclined plates created a buffer between the sludge layer and the influent, and between the clarifier and downstream dewatering stage. This limited the build-up of solids on the plates and minimized the risk of re-entrainment and solids carryover, helping their clogging and short-circuiting issues to disappear. Furthermore, the thickener increased the settled sludge concentration, leading to reduced dewatering costs.

Pilot Study Results

The pilot study demonstrated the significant advantages of the Monroe Lamella Plate Clarifier system versus the existing system. Key results included:

- Elimination of Short-Circuiting – The optimized mixing and flocculation design improved the flow patterns and effectively minimized solids settling in the pre-treatment tanks.

- Improved Effluent Quality – The combination of proper design geometry, solids handling, and enhanced clarification effectively eliminated solids carryover in the effluent, which lowered their outlet TSS.

- Reduced Maintenance & Maximized Uptime – Fewer shutdowns to clean the pre-treatment tanks and the clarifier plates meant more uptime for the plant.

Outcome

Based on the overwhelmingly positive results of the pilot study, the customer purchased a full-scale 750 GPM Monroe Vertical Clarifier with Sludge Thickener for their wastewater treatment process. The successful pilot program provided the confidence and data needed to invest in a long-term, reliable solution to improve effluent quality, reduce maintenance, and optimize downstream processes.