The advanced design of the Monroe Spiral Tube Mist Collectors provide maximum mist and oil collection efficiency in a mechanical collector. These units have a lower lifetime cost of ownership than other filtration mist collectors because of reduced filter replacement costs. Air processed by the Monroe Spiral Tube Mist Collectors meet air quality standards for in-plant discharge as well as outside exhaust. Discharging clean, filtered air back into the work area can significantly reduce climate control costs.

Spiral Tube Mist Collector Design

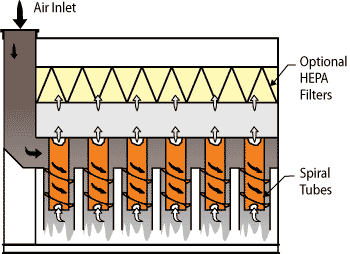

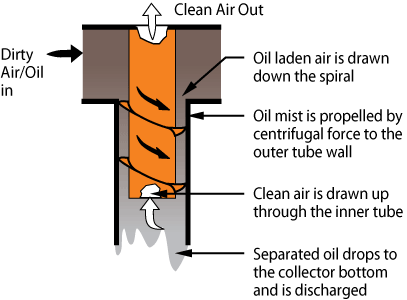

The Monroe Spiral Tube Mist Collector is a two stage unit and does not require filter media for primary mist removal. The spiral tubes provide a high level of mist agglomeration and removal without using filters. Centrifugal force and impaction provide the mechanism for mist removal.

Dirty air is propelled down several spiral shaped impaction tubes and a fluid film is created. The oil drains into the collector bottom. Air changes direction 180°, then enters the second stage HEPA type filter typically rated at a minimum 95% efficiency at 0.3 micron particle size.

Ideally suited for production machining operations with water soluble, synthetic or mineral coolants.

Mist & Oil Re-Entrainment Eliminated

Due to the unique internal design of the Monroe Mist Collector, the cleaned air will not re-entrain collected pollutants after the primary stage. This improves the efficiency of the separation process and extends the life of the optional final filters.

Higher Efficiency Design

The Monroe Spiral Tube Mist Collectors provide maximum mist and oil collection efficiency in a mechanical collector. Air processed by the Monroe Spiral Tube Mist Collectors meet air quality standards for in-plant discharge as well as outside exhaust. Discharging clean, filtered air back into the work area can significantly reduce climate control costs.

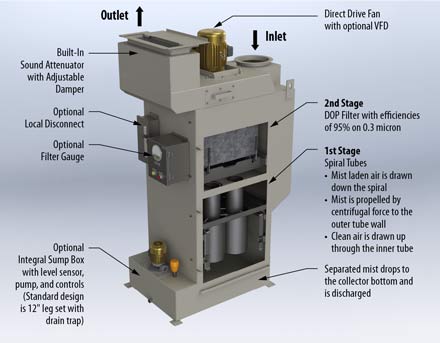

Compact Spiral Tube Mist Collector: Low-Profile, Reduced Footprint Design

The Compact Spiral Tube Mist Collector combines the cost saving and maintenance-reducing benefits of mechanical separation (verses consumable filters) with a low-profile, reduced-footprint design that saves floor space and minimizes integration and layout challenges in the modern production plant. The unit can be integrated into any machining operation or can stand alone to exhaust operations using water soluble, synthetic, or mineral cutting fluids.

- Mist, smoke and vapor removal

- Capacities from 500 to 1,200 CFM

- Low energy requirement

- Continuous draining during operation

- Low maintenance

- Machine mounting capabilities

- Welded construction