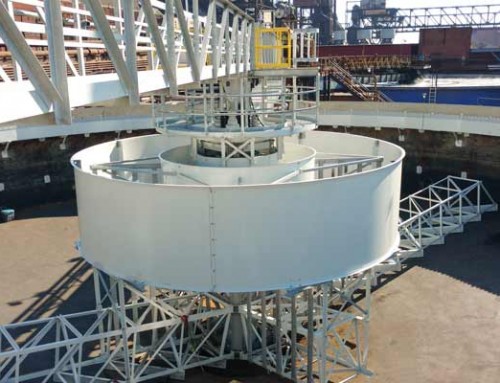

Solids Contact Clarifier for Paperboard Mill Installed in Just Two Weeks

Challenge

A large paperboard mill required a complete overhaul of its 90-foot solids clarifier, and had just two weeks to get it done to avoid production losses. The clarifier treated 11 MGD of raw water for turbidity, TSS, and color removal. The existing unit was decades old and had an uncommon arrangement that required extensive redesign.

Solution

Monroe’s team engineered a new custom Solids Contact Clarifier with a specialized turbine impeller to fit into the existing tank. In order to hit the two-week downtime window, Monroe had to ensure that all the parts fit together perfectly in the field prior to installation. To do this, Monroe pre-fit the assembly in their shop prior to shipment. Once on-site, our Field Service team directed additional pre-assembly in a staging area to streamline the installation process.

Result

Despite supply chain hurdles, the unit was fabricated and delivered on time. With our Field Service Technician delivering 24/7 on-site support, the installation was completed within the two-week shutdown window. The mill achieved immediate success, meeting its effluent targets (<1 NTU) from the first day of operation. This project showcased Monroe’s ability to deliver complex, time-sensitive, engineered solutions for a high-production plant without sacrificing quality.