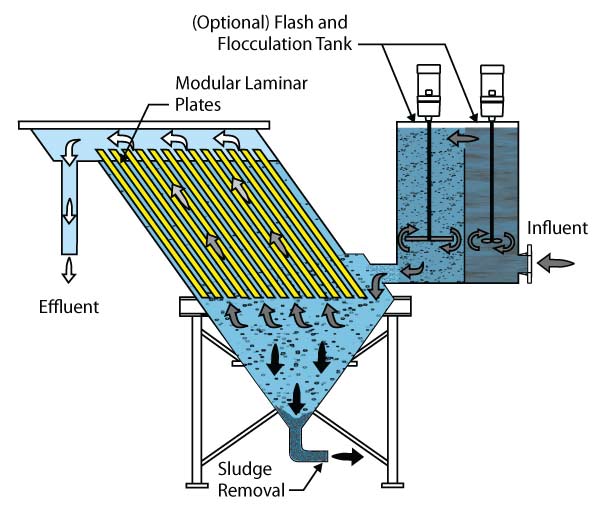

Are you facing challenges with budgets, limited space, or elevated solids in your water treatment processes? Monroe Environmental’s Lamella Plate Vertical Clarifiers are engineered for high-efficiency solids removal in a compact footprint — delivering up to ten times the settling area of conventional clarifiers at a lower cost.

Why Choose Monroe’s Lamella Plate Vertical Clarifier?

Monroe also offers versatile Horizontal Plate Clarifiers which utilize cross-flow parallel plate technology capable of removing floating contaminants as well as settleable materials, all with a lower total height requirement.

Vertical Clarifier Applications

- TSS, solids/particulate removal

- Dissolved solids and metals precipitation

- Ballasted flocculation

- Pre-treatment for filtration/membrane processes

- Filter backwash clarification

- Leachate clarification

- Industrial process water clarification

- Cooling tower water clarification

- Surface/raw water treatment

- Water recycling/reuse

- Municipal and industrial processes

Vertical Plate Clarifier Case Studies

Water | Wastewater Clarifiers Meet New Molybdenum Regulations at Hazardous Waste Landfill

A hazardous waste landfill required an upgrade to its wastewater treatment system to comply with new, more stringent molybdenum regulations. Monroe Environmental helped design and implement a solution.

Water | Vertical Plate Clarifier Removes Mercury & Humic Acid

A company that produces testing and measurement equipment needed to remove solids containing mercury and acid fines from their incoming process water stream.

Water | Lamella Clarifier Retrofit

Rebuild of two underperforming Lamella Clarifiers to address the stresses of elevated liquid temperatures, and internal structural and process deficiencies.

Water | Lamella Plate Clarifier Pilot Confirms Solution to Reduce TSS

Based on the overwhelmingly positive results from the 50 GPM pilot lamella clarifier study, The customer purchased a full-scale Monroe 750 GPM Lamella Plate Vertical Clarifier system for their wastewater treatment process.

Designed for Your Process — Options to Enhance Efficiency

Clarifier Maintenance Made Simple

One of the key advantages of inclined plate clarifiers is minimal maintenance. With no mechanical components within the plate packs, routine upkeep is straightforward and infrequent. Operators typically need only perform periodic visual inspections and occasional rinsing to ensure continued efficiency—helping to keep your maintenance routines simple and non-disruptive.

Keep your system running at peak efficiency with our Monroe Plate Cleaning Wand—clean separator plates in place, even while the unit is operating. Learn more.

Power and Operational Cost Considerations

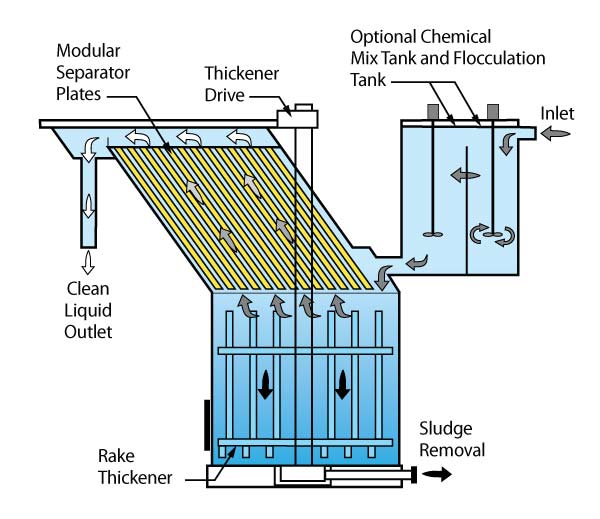

Inclined plate clarifiers are engineered for efficiency, with modest power demands compared to many traditional separation systems. Their design typically utilizes slow-moving drives and low-horsepower motors—often requiring less energy than conventional clarifiers or mechanical alternatives.

This efficient operation helps to substantially reduce ongoing operational costs, making these clarifiers a cost-effective solution for both municipal and industrial facilities. The simplified mechanics not only cut down on energy expenses, but also minimize maintenance needs over the long term, adding further value to the system’s lifecycle.

Enhanced Safety & Compliance

- Covers to prevent algae, limit vapor/fume exposure, and protect water quality

- Complete electrical controls and access solutions

- Customizable ladders, platforms, and railings for your facility

Resources & Literature

-

Applications & Solutions by Industry

-

Assessments and Equipment Evaluations

-

Rental, Pilot & Testing Programs

-

Case Studies

-

Recent Projects

-

Return to all Water & Wastewater Treatment Equipment

-

Learn more about Monroe’s Air Pollution Control Equipment

-

Vertical Plate Clarifiers

-

Monroe Plate Cleaning Wand Tool

-

Water & Wastewater Treatment (Overview of Systems, Services & Solutions)

-

Water & Wastewater Treatment (Equipment & Systems Design)

- Launder, mixer, drive access

- Installation of (2) clarifiers

- Vertical Clarifier w/ thickener

- Landfill leachate clarifier

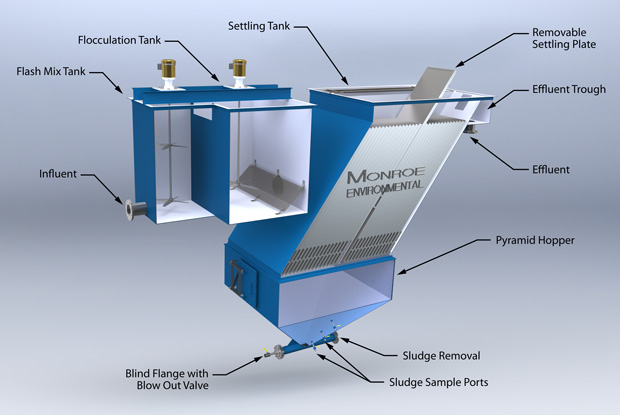

- 1,000 GPM w/ pyramid hopper

- Disc filter backwash clarifier

- Sand filter backwash at WTP

- FRP construction with cover

- Shop assembly before shipment

- Pilot vertical clarifier rental

- Launder, mixer, drive access

- Installation of (2) clarifiers

- Vertical Clarifier w/ thickener

- Landfill leachate clarifier

- 1,000 GPM w/ pyramid hopper

- Disc filter backwash clarifier

- Sand filter backwash at WTP

- FRP construction with cover

- Shop assembly before shipment

- Pilot vertical clarifier rental