Effective Emissions Control for Acids, Particulate Matter, Condensables, and Opacity

High-Efficiency Wet Scrubbers for Air Quality Compliance

At Monroe Environmental, we understand that managing air emissions is critical — both for regulatory compliance and for protecting your workforce and neighboring communities. Our Wet Scrubber Systems offer a reliable, efficient solution for removing particulate matter, acid gases, and industrial fumes from your exhaust streams.

When your process involves complex or corrosive air streams, you need more than just a piece of equipment; you need application expertise. We specialize in controlling a diverse range of air pollutants, with removal efficiencies > 99% in many installations.

Whether you need a Packed Tower Scrubber for gas absorption, or a Venturi Scrubber or Wet ESP for fine particulate removal, Monroe provides custom-engineered wet scrubber systems optimized for your process and compliance goals.

Why Work with Monroe Environmental?

What is a Wet Scrubber?

A wet scrubber uses a liquid—typically water or a water-based chemical solution—to capture pollutants in a gas stream. The pollutant-laden air passes through the system where it contacts the liquid droplets, allowing harmful substances to be absorbed, neutralized, or collected before the clean air is released.

Why Choose Monroe’s Wet Scrubbers?

We offer a full line of custom wet scrubbers, fabricated to handle the specific chemistry, physical characteristics, temperature, and volume of your air stream.

Featured Wet Scrubber Technologies

We offer a full line of custom wet scrubbers, fabricated to handle the specific chemistry, temperature, and volume of your air stream.

Operational and Maintenance Considerations for Wet Scrubber Systems

Proper operation and regular maintenance are critical to achieving optimum performance from wet scrubber systems. One key aspect is monitoring the liquid management system. This typically includes liquid level instruments, water make-up valves, blowdown valves, drains, and overflow ports attached to the scrubber. Some systems may also include pH or conductivity probes that assist with liquid management and control of scrubbing liquor chemical properties.

Additionally, mist eliminators, cyclones, and separators need to be maintained so they efficiently separate entrained droplets and particles from the cleaned gas stream—preventing carry over into downstream equipment. This typically involves monitoring differential pressure, as well as periodic inspections and/or cleaning to ensure that functionality is not hindered by scaling or solids accumulation.

For systems like Venturi Scrubbers and Packed Bed Scrubbers, overall collection efficiency often depends on maintaining adequate liquid flows and system pressures. Routine checks of pumps, nozzles, fans, instruments, and piping help to sustain desired performance levels.

By paying close attention to these factors—scrubbing liquid management, mist eliminator maintenance, and system flows and pressures—plants can help ensure reliable, long-term operation of their wet scrubbing systems.

Let Monroe Help Maintain Your Scrubbers

Monroe offers preventative maintenance services for all types of wet scrubber systems. We can provide a recurring PM contract, or one-time “tune up” service – whichever is most beneficial for your plant. These always include a written assessment/service report with each visit.

Wet Scrubber Applications

Our Wet Scrubber solutions are ideal for a wide range of industries, including:

Complete Systems Integration

We integrate all components for turn‑key delivery:

End-to-End Service & Support

From the initial process assessment to on-site testing and installation, Monroe Environmental is your single-source solution. We also offer comprehensive services to maximize the longevity and performance of your existing equipment, including:

Next Steps: Request a Quote for Your Plant’s Wet Scrubber

Reach out to us for a site review and emissions assessment or preventative maintenance visit. Let us help you determine whether a wet scrubber is the right solution—and what optimal design looks like for your facility.

Call 800-992-7707 or request a quote online to connect with a Monroe Expert and get a solution tailored to your needs.

Proudly serving facilities across North America with proven, U.S.–based engineering and support.

Recent Case Studies

Air | Extending the Life of an Existing Fume Scrubber

Monroe Environmental is expert in troubleshooting and rebuilding a competitor’s wet scrubbing system to bring it up to like-new efficiency and performance standards.

Air | Packed Tower Wet Scrubber – SO2 Removal

Monroe Packed Tower Wet Scrubber for wastewater treatment plant to absorb and neutralize SO2 from bio-solids incineration exhaust.

Air | Packed Bed Scrubber Solves Toxic Gas Issues

30,000 CFM Horizontal Packed Bed Wet Scrubber System absorbs and neutralizes acid gasses from acid dip tanks.

Air | Halide Recovery at a Major Glass Products Plant

Custom designed Multi-Stage System – process gasses treated with a series of scrubbers, and wastewater was treated with a Monroe compact clarifier.

Air | Glass Resin Scrubbing System

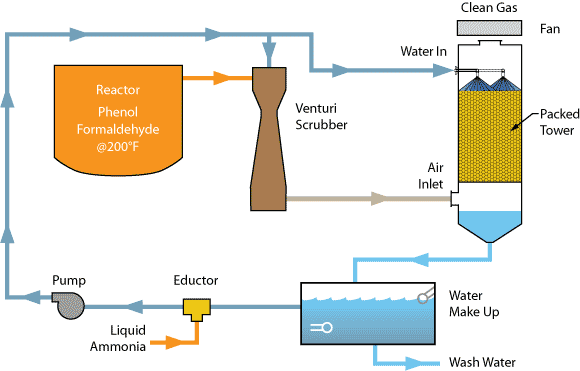

Custom designed Multi-Stage System to provide high efficiency scrubbing of the phenol & formaldehyde, as well as separation and removal of the dust particulate.

Air | Multi-Stage Scrubbing System for Incinerator Exhaust

Monroe Environmental provided a multi-stage wet air scrubbing system for HCl and particulate removal from incinerator exhaust at an industrial waste plant.