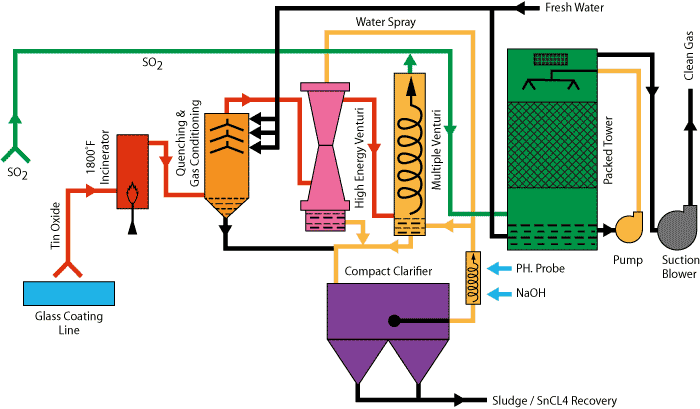

Monroe Scrubbing System Provides Halide Recovery at a Major Glass Products Plant

Challenge

A glass manufacturing plant was having trouble cleaning the emitted gasses, particulate, and odors that resulted from its manufacturing process. Metallic halides such as SnCl4 and TiCl4 were being applied to hot glass to impart special properties. The halide and oxide emissions were hazardous, extremely pungent, irritating in odor, and very difficult to scrub.

Solution

Monroe designed and manufactured a comprehensive treatment system in which the process gasses were treated successfully with series of scrubbers, while the wastewater was treated separately with a Monroe compact clarifier. The tin sludge was reclaimed and the costly tin oxide was recovered after the clarification process.

The fully automated scrubbing system consisted of a unique combination of a high-energy Venturi Scrubber with a Multiple Venturi Scrubber for high efficiency and recovery, as well as a Packed Tower Scrubber for the removal of SO2 from the air stream. The system required minimum maintenance and was controlled by a PLC. The PLC integrated the safety of the combustor and the scrubbing system, which provided fast system reaction.

Result

The final outlet efficiency of the system was roughly 99.5%. This allowed the manufacturer to recover and reuse the costly halides, saving time and money associated with purchasing. In addition, the odorous fumes emitted from the system were successfully treated.